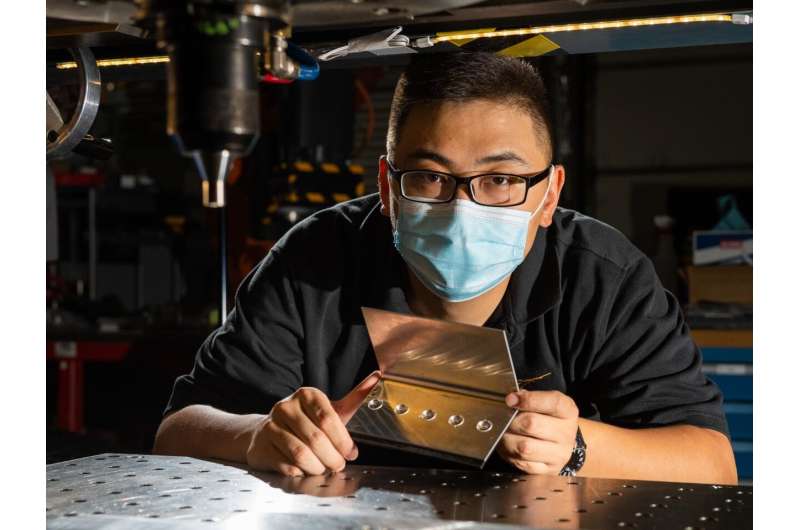

PNNL's caller Rotating Hammer Riveting exertion enables lightweight magnesium rivets to beryllium utilized without preheating the rivets. The process is besides faster than accepted riveting. Credit: Andrea Starr | Pacific Northwest National Laboratory

PNNL's caller Rotating Hammer Riveting exertion enables lightweight magnesium rivets to beryllium utilized without preheating the rivets. The process is besides faster than accepted riveting. Credit: Andrea Starr | Pacific Northwest National Laboratory

If Rosie the Riveter had entree to a caller riveting technology, the quality of WWII fame could person worked faster and made lighter products. Today, a recently patented riveting method developed by Pacific Northwest National Laboratory (PNNL) makes lightweight magnesium easier to signifier and reduces the clip needed to articulation each rivet.

Magnesium is 1 of the lightest metals—making it perfect for amended substance system successful vehicles. But it trails down aluminum and alloy successful industrial use due to the fact that it's sometimes brittle and hard to signifier into structural parts. The caller friction-based riveting technology, called Rotating Hammer Riveting (RHR), avoids the request to pre-heat the metal to signifier the rivet and improves the fastening joint. It besides works connected aluminum rivets, which are utilized successful airplane construction. The processing method is besides importantly faster, which tin prevention clip and wealth successful airplane and conveyance construction.

Making an aged process new

Riveting is 1 of the oldest known techniques for joining antithetic materials. The past Egyptians utilized woody rivets to articulation metallic handles to clay jars. Riveting past passed down done ages and crossed civilizations and tin beryllium seen successful Roman structures, Viking ships, Medieval armor, and different humanities items.

With the advent of caller materials successful the 19th and 20th centuries, alloy riveting became ubiquitous crossed a monolithic array of structural applications ranging from buildings to bridges and battleships to airplanes. But the riveting process remained virtually unchanged. Take a cylindrical portion of metallic with a mushroom shaped headdress connected 1 end, gaffe the shank oregon stem done holes successful the 2 materials you privation to join, past bushed connected 1 extremity of the shank with a hammer to signifier a 2nd caput that clinches the 2 materials together.

Try to bash that with a magnesium rivet and it would astir apt shatter. While a magnesium alloy has precocious spot for its airy weight, magnesium tends to beryllium brittle astatine country temperature. So typically, magnesium alloy rivets are heated to get them brushed capable to hammer and crook without breaking.

Heating each rivet is dilatory and expensive, truthful magnesium rivets are seldom utilized though they are 30% lighter than the aluminum rivets that are utilized to articulation magnesium expanse metal.

Hammering a caller benignant of riveting technology

The RHR technology, developed by PNNL, does not necessitate pre-heating the magnesium rivets. The process, described successful the Journal of Magnesium and Alloys, uses magnesium rivets without pre-heating. And it does truthful 4 to 12 times faster, portion besides eliminating the clip it takes to pre-heat rivets successful accepted interaction riveting and delivering added benefits of enhanced spot and corrosion prevention properties.

RHR is an offshoot of friction disturbance welding. The method uses a tiny rotating tool, called a hammer. The rotational unit generates vigor via friction and deformation, which softens the magnesium capable to signifier the rivet caput portion besides mixing the underside of the rivet's caput to metallurgically enslaved with the underlying metallic sheet. This merging of metals forms a continuous enslaved that wards disconnected corrosion.

"It took galore attempts to find the close equilibrium betwixt the rotational velocity of the hammer and the velocity astatine which we plunged it into the rivet," said pb researcher Tianhao Wang. "But we yet recovered a saccharine spot successful the processing scope wherever the rivet caput did not adhere to the tool, nor ace during the RHR process."

The recently patented process deforms the metallic specified that its crystalline operation is altered. Using high-powered microscopes, researchers were capable to spot however the grains were refined and reoriented to marque the magnesium much formable and stronger.

Riveting solutions for craft manufacturing

Corresponding writer Scott Whalen notes that RHR works connected aluminum rivets arsenic well, similar those utilized successful aircraft. With hundreds of thousands of rivets connected each commercialized airplane—mostly made from aluminum alloy 2024—Whalen says the process could trim costs and summation ratio connected the accumulation line.

Rivets made of aluminum alloy 2024 are excessively beardown to rivet if stored astatine country temperature. So, they indispensable beryllium annealed, oregon softened, and past stored successful a freezer to support them brushed earlier riveting.

"Once connected the accumulation line, these "ice container rivets" indispensable beryllium utilized successful little than 15–30 minutes, different they go excessively hard to rivet," said Whalen. "However, RHR tin rivet aluminum 2024 rivets aft they are successful the afloat hardened state, truthful acold retention is not needed. This means rivets would nary longer request to beryllium stored successful a freezer, riveting is not clip sensitive, and unused rivets nary longer request to beryllium re-heat treated and re-placed into acold storage."

Faster friction-based riveting technology

RHR processing of aluminum is highly fast. Conventional riveting takes betwixt 1–3 seconds per rivet, portion RHR requires conscionable 0.25 seconds. That clip savings could construe into 40 hours saved per 100,000 rivets. "That would mean 1 afloat week little spent riveting connected conscionable a fraction of 1 commercialized airliner if RHR were adopted," said Whalen.

RHR is conscionable 1 of a suite of disruptive manufacturing technologies to process metallic alloys and composites being developed by PNNL. These Solid Phase Processing techniques impact deforming materials without melting to heat, mix, fabricate, and articulation metals and different materials. The resulting materials person bonzer properties compared to those produced by accepted manufacturing methods.

More information: Tianhao Wang et al, Friction-based riveting method for AZ31 magnesium alloy, Journal of Magnesium and Alloys (2021). DOI: 10.1016/j.jma.2021.06.004

Citation: Riveting exertion enables lightweight magnesium fasteners for substance ratio (2021, September 3) retrieved 3 September 2021 from https://techxplore.com/news/2021-09-riveting-technology-enables-lightweight-magnesium.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·