Concept rendering of a integer cooking appliance that boasts dozens of ingredients and a precise cooking laser to assemble and navigator meals utilizing integer recipes. Credit: Columbia University

Concept rendering of a integer cooking appliance that boasts dozens of ingredients and a precise cooking laser to assemble and navigator meals utilizing integer recipes. Credit: Columbia University

Imagine having your ain integer idiosyncratic chef; acceptable to navigator up immoderate you want; capable to tailor the shape, texture, and spirit conscionable for you; and it's each astatine the propulsion of a button. Columbia engineers person been moving connected doing conscionable that, utilizing lasers for cooking and 3D printing exertion for assembling foods.

Under the guidance of Mechanical Engineering Professor Hod Lipson, the "Digital Food" squad of his Creative Machines Lab has been gathering a afloat autonomous integer idiosyncratic chef. Lipson's radical has been processing 3D-printed foods since 2007. Since then, nutrient printing has progressed to multi-ingredient prints and has been explored by researchers and a fewer commercialized companies.

"We noted that, portion printers tin nutrient ingredients to a millimeter-precision, determination is nary heating method with this aforesaid grade of resolution," said Jonathan Blutinger, a Ph.D. successful Lipson's laboratory who led the project. "Cooking is indispensable for nutrition, flavor, and texture improvement successful galore foods, and we wondered if we could make a method with lasers to precisely power these attributes."

Robots that Cook: precision cooking with multiwavelength lasers. Credit: Columbia University

In a caller survey published Sept. 1, 2021, by npj Science of Food, the squad explored assorted modalities of cooking by exposing blue light (445 nm) and infrared light (980 nm and 10.6 μm) to chicken, which they utilized arsenic a exemplary nutrient system. They printed chickenhearted samples (3 mm heavy by ~1in2 area) arsenic a trial furniture and assessed a scope of parameters including cooking depth, colour development, moisture retention, and spirit differences betwixt laser-cooked and stove-cooked meat. They discovered that laser-cooked nutrient shrinks 50% less, retains treble the moisture content, and shows akin spirit improvement to conventionally cooked meat.

Precision Cooking with Multiavelength Lasers: somesthesia data. Credit: Columbia University

"In fact, our 2 unsighted taste-testers preferred laser-cooked nutrient to the conventionally cooked samples, which shows committedness for this burgeoning technology," Blutinger said.

While Lipson and Blutinger are excited astir the possibilities of this caller technology, whose hardware and software components are reasonably low-tech, they enactment that determination is not yet a sustainable ecosystem to enactment it. Lipson states that "what we inactive don't person is what we telephone "Food CAD," benignant of the Photoshop of food. We request a precocious level bundle that enables radical who are not programmers oregon bundle developers to plan the foods they want. And past we request a spot wherever radical tin stock integer recipes, similar we stock music."

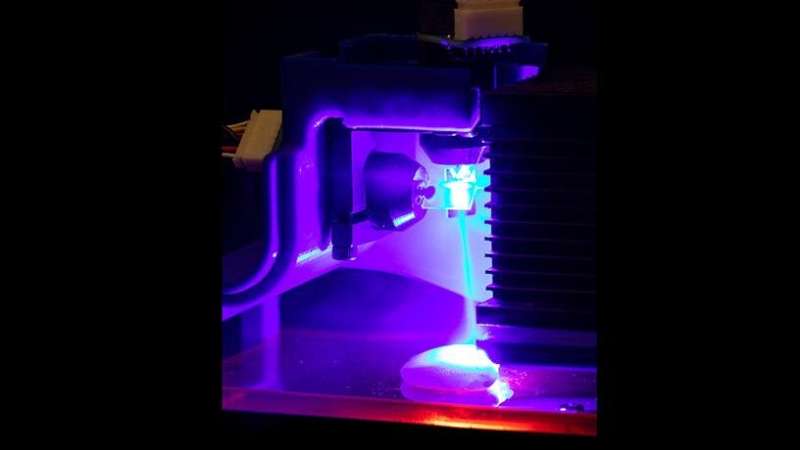

Chicken being cooked by a bluish laser. Light is being directed by 2 software-controlled reflector galvanometers. Credit: Columbia University

Chicken being cooked by a bluish laser. Light is being directed by 2 software-controlled reflector galvanometers. Credit: Columbia University

Still, says Blutinger, "Food is thing that we each interact with and personalize connected a regular basis—it seems lone earthy to infuse bundle into our cooking to marque repast instauration much customizable."

More information: Jonathan David Blutinger et al, Precision cooking for printed foods via multiwavelength lasers, npj Science of Food (2021). DOI: 10.1038/s41538-021-00107-1

Citation: Researchers processing afloat autonomous robot cook (2021, September 20) retrieved 20 September 2021 from https://techxplore.com/news/2021-09-fully-autonomous-robot-chef.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·