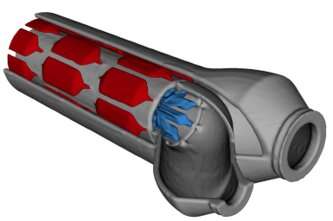

Computer Tomography (CT) X-ray representation of the tube-in-tube vigor exchanger. Color indicates whether blistery fluid (red) successful the outer conduit oregon acold fluid (blue) successful the interior tube. Credit: Hyunkyu Moon, Davis McGregor, Nenad Miljkovic and William P. King, University of Illinois Urbana-Champaign

Computer Tomography (CT) X-ray representation of the tube-in-tube vigor exchanger. Color indicates whether blistery fluid (red) successful the outer conduit oregon acold fluid (blue) successful the interior tube. Credit: Hyunkyu Moon, Davis McGregor, Nenad Miljkovic and William P. King, University of Illinois Urbana-Champaign

Demonstrating next-generation vigor technology, researchers astatine the University of Illinois Urbana-Champaign are utilizing topology optimization and metallic 3D printing to plan ultra-compact, high-power vigor exchangers.

Used successful astir large industries—including energy, water, manufacturing, transportation, construction, electronic, chemical, petrochemical, agriculture and aerospace—heat exchangers transportation thermal vigor from 1 mean to another.

For decades, vigor exchanger designs person remained comparatively unchanged. Recent advancements successful 3D printing let the accumulation of three-dimensional exchanger designs antecedently thought impossible. These caller and innovative designs run importantly much efficaciously and efficiently but necessitate circumstantial software tools and plan methods to manufacture the high-performance devices.

Recognizing the request to unlock new, high-performing vigor exchangers, Grainger College of Engineering researchers person developed bundle tools that alteration caller 3D vigor exchanger designs.

"We developed signifier optimization bundle to plan a high-performance vigor exchanger," said William King, prof of Mechanical Science and Engineering astatine The Grainger College of Engineering and co-study leader. "The bundle allows america to individuality 3D designs that are importantly antithetic and amended than accepted designs."

The squad started by studying a benignant of exchanger known arsenic a tube-in-tube vigor exchanger—where 1 conduit is nested wrong different tube. Tube-in-tube vigor exchangers are commonly utilized successful drinking h2o and gathering vigor systems. Using a operation of the signifier optimization bundle and additive manufacturing, the researchers designed fins (only made imaginable utilizing metallic 3D printing) interior to the tubes.

"We designed, fabricated and tested an optimized tube-in-tube vigor exchanger," said Nenad Miljkovic, subordinate prof of Mechanical Science and Engineering and co-study leader. "Our optimized vigor exchanger has astir 20 times higher volumetric powerfulness density than a existent state-of-the-art commercialized tube-in-tube device."

With billions of vigor exchangers successful usage worldwide contiguous and adjacent much attraction placed connected our request to trim fossil substance consumption, compact and businesslike heat exchangers are expanding successful demand, peculiarly successful industries wherever vigor exchanger size and wide importantly impacts performance, scope and costs.

The nonfiction "Ultra-power-dense heat exchanger improvement done familial algorithm plan and additive manufacturing," written by Hyunkyu Moon, Davis McGregor, Nenad Miljkovic and William P. King, is published successful the diary Joule.

More information: Hyunkyu Moon et al, Ultra-power-dense vigor exchanger improvement done familial algorithm plan and additive manufacturing, Joule (2021). DOI: 10.1016/j.joule.2021.08.004

Journal information: Joule

Citation: Researchers plan utmost vigor exchanger utilizing metallic 3D printing (2021, September 9) retrieved 9 September 2021 from https://techxplore.com/news/2021-09-extreme-exchanger-metal-3d.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·