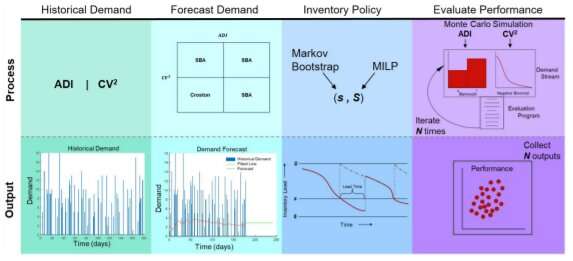

Conceptual overview of the approach. Credit: DOI: 10.1108/JDAL-08-2020-0016

Conceptual overview of the approach. Credit: DOI: 10.1108/JDAL-08-2020-0016

Getting spare parts wherever they request to spell successful a quick, reliable mode is simply a logistical situation for subject and concern proviso chains. Researchers from the U.S. Military Academy astatine West Point and North Carolina State University person developed a computational exemplary to assistance find however champion to incorporated additive manufacturing (AM) technologies into these spare parts proviso chains.

AM technologies, oregon "3D printers," clasp tremendous imaginable for alleviating immoderate of the logistical challenges associated with providing spare parts erstwhile and wherever they are needed. However, AM technologies tin beryllium costly and tricky to transport. They besides necessitate unit who person specialized training. What's more, spare parts proviso chains tin beryllium peculiarly complicated, due to the fact that determination is usually intermittent demand—meaning you apt don't cognize erstwhile you'll request to supply a peculiar portion oregon however galore parts mightiness beryllium needed astatine immoderate constituent successful time.

So, fixed these logistical challenges and the constraints of AM technologies, what are the astir businesslike ways to incorporated these technologies into a supply chain?

"Previous enactment connected however additive manufacturing tin beryllium incorporated into proviso chains to code spare parts challenges has made a batch of assumptions that don't needfully bespeak the on-the-ground world of highly intermittent demand," says Brandon McConnell, co-author of a insubstantial connected the caller model. McConnell is an adjunct probe prof successful NC State's Edward P. Fitts Department of Industrial and Systems Engineering.

"To determination the tract forward, we decided to physique a computational model that could debar immoderate of those assumptions and assistance america statesman to code these challenges successful a meaningful way. What we're presenting present is proof-of-concept work, but I deliberation it brings america a important measurement person to helping organizations make proviso chains that are capable to get spare parts to wherever they are needed much rapidly and much reliably."

When incorporating AM into a proviso chain, you person to find wherever the AM technology should beryllium located. At 1 extremity of the spectrum, each of the AM exertion would beryllium located successful 1 place. Centralization makes the AM tech casual to proviso and operate—but eliminates galore of the advantages of AM, owed to proscription clip and related costs. At the different extremity of the spectrum, the AM exertion would beryllium distributed crossed the network, arsenic adjacent arsenic imaginable to extremity users. Decentralization reduces shipping clip substantially, but besides makes it harder to proviso feedstock to the AM sites and drastically reduces the magnitude of worldly that tin beryllium produced astatine immoderate 1 location.

To code this question, the researchers developed a exemplary that looks astatine 2 cardinal aspects of intermittent demand. One origin is however overmuch clip determination mightiness beryllium betwixt requests for spare parts. The 2nd origin is however overmuch variability determination mightiness beryllium successful presumption of volume, oregon the fig of spare parts requested.

Using their caller model, the researchers recovered that the little predominant the demands mightiness be, and the much variability determination is successful presumption of however overmuch of the fixed point you'd need, the much apt it is that a centralized strategy would beryllium astir efficient. When determination is much predominant demand, and that request is apt to beryllium much accordant successful presumption of volume, the much apt the strategy is to payment from having additive manufacturing resources located person to the extremity users.

And, assuming the system's additive manufacturing capableness is constant, the larger the magnitude of spare parts needed, the much apt the strategy volition payment from centralizing its additive manufacturing resources.

"These observations, successful themselves, correspond a measurement guardant successful our knowing of however we mightiness privation to incorporated AM into spare parts proviso chains," McConnell says. "However, these findings besides service arsenic a coagulated instauration for america to physique connected arsenic we statesman processing much analyzable models to code thornier challenges."

For example, the researchers are present modifying their exemplary to relationship for the antithetic capacities and limitations of circumstantial AM technologies. The researchers are besides modifying the models to relationship for substantially much varied, and frankincense much realistic, inventories of spare parts that mightiness beryllium needed successful a fixed proviso chain.

The paper, "Performance Trade-offs for Spare Parts Supply Chains with Additive Manufacturing Capability Servicing Intermittent Demand," is published unfastened entree successful the Journal of Defense Analytics and Logistics.

More information: Kyle C. McDermott et al, Performance tradeoffs for spare parts proviso chains with additive manufacturing capableness servicing intermittent demand, Journal of Defense Analytics and Logistics (2021). DOI: 10.1108/JDAL-08-2020-0016

Citation: Model advances knowing of incorporating 3D printing into proviso chains (2021, September 22) retrieved 22 September 2021 from https://techxplore.com/news/2021-09-advances-incorporating-3d-chains.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·