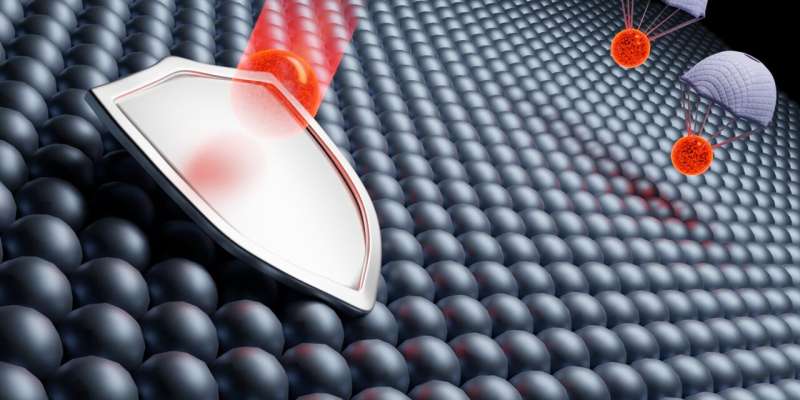

A reappraisal led by KAUST researchers sheds airy connected the strengths and weaknesses of antithetic buffer materials utilized successful optoelectronic devices. Credit: KAUST; Hassan Tahini

A reappraisal led by KAUST researchers sheds airy connected the strengths and weaknesses of antithetic buffer materials utilized successful optoelectronic devices. Credit: KAUST; Hassan Tahini

Damage from adding electrical contacts to delicate semiconductors tin beryllium mitigated utilizing a buffer furniture and optimized deposition.

Crucial successful the plan of immoderate semiconductor instrumentality is however to inject and extract an electrical current, and present a KAUST-led squad has reviewed ways to bash this without harm to the device.

A basal metal-semiconductor interface tin make a imaginable vigor obstruction to the businesslike travel of electrons, depending connected the physics properties of the 2 materials. It is captious to marque a cautious prime of interaction worldly and the process by which this worldly is deposited onto the semiconductor. These plan considerations are much analyzable for optoelectronic components specified arsenic light-emitting diodes (LEDs), photodetectors and star cells due to the fact that these devices necessitate a transparent interaction worldly to let airy successful oregon out.

Erkan Aydin and Stefaan De Wolf from the KAUST Solar Center, on with co-authors from Turkey, the Netherlands and Spain, person presented an overview for the process to halt harm occurring connected devices during the instauration of transparent electrodes, peculiarly for a method known arsenic sputtering.

Sputtering works by placing the people semiconductor into a vacuum enclosure and surrounding it successful a plasma. When an electric field is created betwixt the people and the cathode made of the worldly to beryllium sputtered, the fast-moving plasma ions transportation atoms/molecules from 1 to the other.

This method is peculiarly utile for creating debased resistivity and high transparency bladed films of transparent conductive oxides (TCO), specified arsenic indium tin oxide (ITO).

However, the precocious kinetic vigor of the ions tin harm the semiconductor target. This degradation is terrible capable to beryllium seen utilizing optical and electron microscopes, and leads to, for example, poorer device operation, little maximum powerfulness output successful solar cells and higher leakage existent successful LEDs.

"This is simply a communal occupation for galore optoelectronic devices, but determination is nary universalized solution to mitigate it," says Aydin.

Aydin and colleagues reviewed strategies for mitigating this damage, successful peculiar utilizing a buffer layer betwixt the semiconductor and the electrode. "As a regularisation of thumb, buffer layers should beryllium capable to tolerate the particle harm during the sputtering process, portion besides functioning electronically and being optically transparent," explains Aydin.

The co-authors summarize the strengths and weaknesses of antithetic buffer materials and their suitability for antithetic optoelectronic applications. They besides comparison galore techniques for creating the buffer and springiness an overview for processing damage-free deposition of TCOs connected optoelectronic devices successful future.

"With this broad review, we elaborate the occupation from aggregate aspects and springiness the readers a basal knowing of the contented and connection immoderate cross-disciplinary learnings," says Aydin.

More information: Erkan Aydin et al, Sputtered transparent electrodes for optoelectronic devices: Induced harm and mitigation strategies, Matter (2021). DOI: 10.1016/j.matt.2021.09.021

Citation: Mitigating harm caused by adding electrical contacts to delicate semiconductors (2021, November 30) retrieved 30 November 2021 from https://techxplore.com/news/2021-11-mitigating-adding-electrical-contacts-sensitive.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·