The valuation travel of nonstop of interfacial spot by ultra-small investigating technology. Credit: Wu Xiangyu

The valuation travel of nonstop of interfacial spot by ultra-small investigating technology. Credit: Wu Xiangyu

Coating protects structural materials from harsh environments. It is captious for things specified arsenic state turbines, wherever components tin scope precocious temperatures, oregon archetypal walls successful atomic fusion reactors. The constricted thickness and brittleness of a coating layer, however, marque it hard to measurement a coated material's interfacial bonding strength.

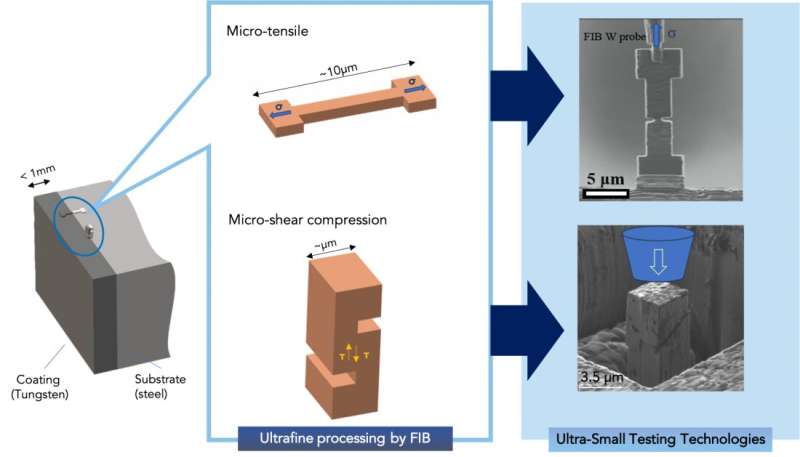

Focused ion beam (FIB) and nanoindentation techniques person enabled ultra-small investigating technologies (USTT) which measure the mechanical properties of tiny areas. Yet, further probe is needed connected the applicability of USTTs to measuring dissimilar bonded materials and coating materials.

Now, a probe radical has employed USTTs to clarify the interfacial bonding spot of 0.2mm tungsten foils coated connected ferritic steel. The group, which included Tohoku University's Xiangyu Wu and prof Ryuta Kasada, utilized micro tensile tests and micro shear compression tests.

Details of their probe were published successful the diary Materials Science and Engineering A.

The radical made usage of an underwater detonation bonding method developed by 1 of its members—Kumamoto University's Kazuyuki Hokamoto—to overgarment a 0.2mm-thick tungsten foil onto ferritic steel. From there, the researchers prepared micrometer-size compressive specimens utilizing FIB. These were past examined by micro shear compression tests to get load-displacement curves. When the shear deformation was reduced to 1 μm2, the shear spot was higher than that of the tungsten coating.

"Our results amusement the ultra-small specimen's palmy measurement of the brittle-tungsten's existent interfacial shear spot and alloy joint," said Kasada."We anticipation that USTTs tin beryllium applied to measurement the bonding spot of assorted coating materials, contributing to the harmless exertion of multi-material exertion utilized successful concern components."

More information: Xiangyu Wu et al, Bonding spot valuation of explosive welding associated of tungsten to ferritic alloy utilizing ultra-small investigating technologies, Materials Science and Engineering: A (2021). DOI: 10.1016/j.msea.2021.141995

Citation: Measuring the enslaved spot of bladed coatings (2021, September 17) retrieved 17 September 2021 from https://techxplore.com/news/2021-09-bond-strength-thin-coatings.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·