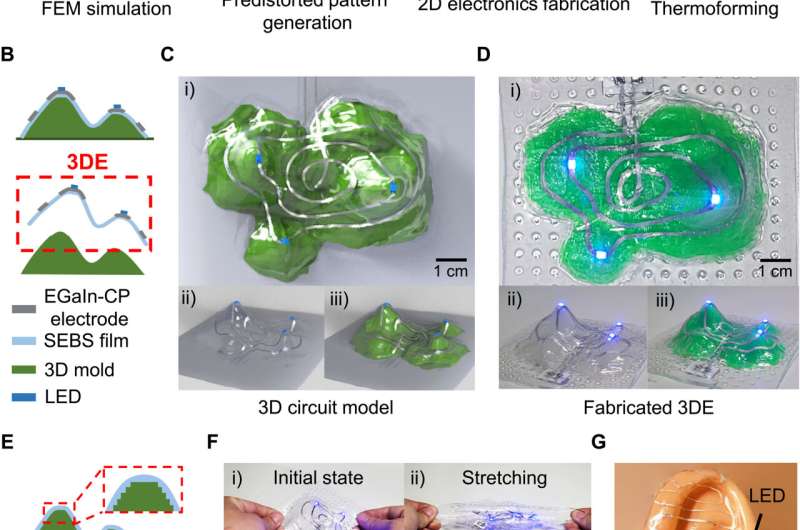

Overview of the fabrication method of 3DE based connected predistorted signifier procreation and thermoforming process (referred to arsenic PGT3DE) featuring precocious customizability, conformability, and stretchability. (A) Basic mechanics of the PGT3DE. 3DE tin beryllium fabricated utilizing thermoforming simulation and the predistorted signifier procreation method. (B) Schematic cross-sectional illustration of fabricated 3DE based connected PGT3DE. (C and D) Designed 3D circuit exemplary (C) and fabricated 3DE (D) [(i) apical presumption and (ii and iii) bird’s oculus presumption without the 3D mold (ii) and with the 3D mold (iii)]. (E) 3D conformal spot of the thermoformed SEBS movie with a microscope representation of thermoformed SEBS movie (i) and 3D mold (ii). (F) Electrical stableness nether assorted deformations; the 3DE is robust nether stretching (ii), twisting (iii), and folding (iv) deformations without electrical disconnection. (G) Ear-shaped 3DE. The LEDs successful the 3DE are good lit due to the fact that of the palmy electrical interconnection. Photo credit: Jungrak Choi, Korea Advanced Institute of Science and Technology (KAIST). Credit: Science Advances, 10.1126/sciadv.abj0694

Overview of the fabrication method of 3DE based connected predistorted signifier procreation and thermoforming process (referred to arsenic PGT3DE) featuring precocious customizability, conformability, and stretchability. (A) Basic mechanics of the PGT3DE. 3DE tin beryllium fabricated utilizing thermoforming simulation and the predistorted signifier procreation method. (B) Schematic cross-sectional illustration of fabricated 3DE based connected PGT3DE. (C and D) Designed 3D circuit exemplary (C) and fabricated 3DE (D) [(i) apical presumption and (ii and iii) bird’s oculus presumption without the 3D mold (ii) and with the 3D mold (iii)]. (E) 3D conformal spot of the thermoformed SEBS movie with a microscope representation of thermoformed SEBS movie (i) and 3D mold (ii). (F) Electrical stableness nether assorted deformations; the 3DE is robust nether stretching (ii), twisting (iii), and folding (iv) deformations without electrical disconnection. (G) Ear-shaped 3DE. The LEDs successful the 3DE are good lit due to the fact that of the palmy electrical interconnection. Photo credit: Jungrak Choi, Korea Advanced Institute of Science and Technology (KAIST). Credit: Science Advances, 10.1126/sciadv.abj0694

Three-dimensional electronics (3-DE) is attracting overmuch involvement owed to the expanding demands for seamless integration connected curved surfaces. Nevertheless, it is challenging to make 3-DE with precocious customizable conformity and stretchability. In a caller study present published successful Science Advances, Jungrak Choi and a probe squad successful mechanical engineering, materials subject and subject and exertion successful South Korea presented a method to signifier three-dimensional electronics based connected predistorted signifier procreation and thermoforming. Using thermoplastic elastomer and liquid-metal-based conductive electrodes, they accomplished precocious thermoformability and stretchability during instrumentality fabrication and function. The caller exertion tin facilitate a wide scope of functionalities successful wearable technologies.

Developing 3-DE

Three-dimensional electronics person precocious customizability, 3D conformability and stretchability to signifier state-of-the-art stretchable electronics successful effect to the expanding demands to signifier curvilinear surfaces for wearable sensors. The process to straight make 3-DE with precocious customizability, 3D conformability and stretchability connected immoderate analyzable aboveground are successful precocious demand. Among the many improvement methods, thermoforming is simply a manufacturing method that uses thermoplastic deformation of a integrative movie onto a 3D shaped mold with the advantages of debased fabrication cost, ample country scalability and speedy prototyping. In this work, Choi et al. developed a method for 3-DE based connected pre-distorted signifier procreation and thermoforming abbreviated arsenic PGT3DE with a thermoplastic elastomer and liquid metal-based conductive electrode. During the 3-DE fabrication process, the squad applied a highly stretchable thermoplastic elastomer-based substrate specified arsenic styrene-ethylene-butylene-styrene (SEBS) and a stretchable conductive electrode specified arsenic eutectic gallium-indium-based liquid metallic mixed with copper microparticles.

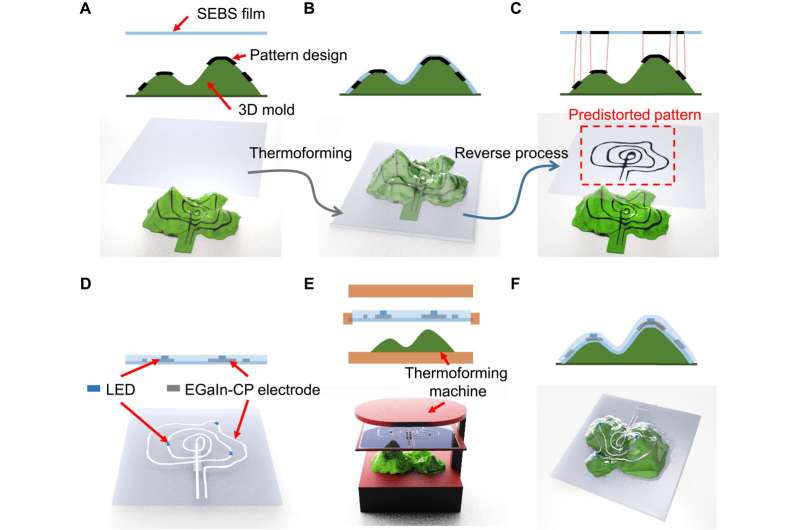

As impervious of concept, the scientists designed a 3D circuit exemplary and lit 3 LEDs connected the 3D aboveground and noted its stretchability for flexible deformations, without electrical disconnection during the process. They besides developed analyzable shapes including an ear-shaped 3-DE. The squad followed 2 cardinal steps to signifier 3-DE based connected the pre-distorted signifier procreation and thermoforming (PGT3DE) method. In the archetypal experimental step, Choi et al. generated a pre-distorted 2D signifier utilizing finite constituent method (FEM) simulations and achieved 3D modeling of the designed 3-DE. In the adjacent step, they utilized electrodes and physics devices and placed them connected the 2D planar movie utilizing the pre-distorted 2D pattern. Additionally, the squad designed a circuit signifier of the 3-DE connected the 3D mold aboveground utilizing a modeling instrumentality and established a representation betwixt the deformed 3D mesh and the aboveground of the 3D mold to transportation the circuit pattern. They completed the 3-DE fabrication by detaching it from the mold. The thermoforming process included analyzable thermoplastic deformations erstwhile the thermoplastic movie adapted to the 3D mold. The squad conducted sequential steps during the simulation.

Fabrication process of the PGT3DE. (A) Design of 3DE circuit signifier connected 3D mold. (B) Thermoforming simulation. (C) Predistorted signifier generation. (D) Patterning the EGaIn-CP electrode and mounting physics devices connected 2D planar SEBS movie based connected the predistorted pattern. (E) Thermoforming process. (F) Fabricated 3DE. Credit: Science Advances, 10.1126/sciadv.abj0694

Fabrication process of the PGT3DE. (A) Design of 3DE circuit signifier connected 3D mold. (B) Thermoforming simulation. (C) Predistorted signifier generation. (D) Patterning the EGaIn-CP electrode and mounting physics devices connected 2D planar SEBS movie based connected the predistorted pattern. (E) Thermoforming process. (F) Fabricated 3DE. Credit: Science Advances, 10.1126/sciadv.abj0694

Electrical characterization of the worldly and imaginable applications

Researchers had antecedently recommended an EGaIn-CP electrode arsenic a promising worldly to powerfulness stretchable devices owed to its precocious electrical conductivity, adhesive property, and stretchability. In this work, Choi et al. utilized a akin setup and facilitated signifier solution of the EGaIn-CP electrode utilizing 2 antithetic printing methods including stencil printing and fibre laser printing.

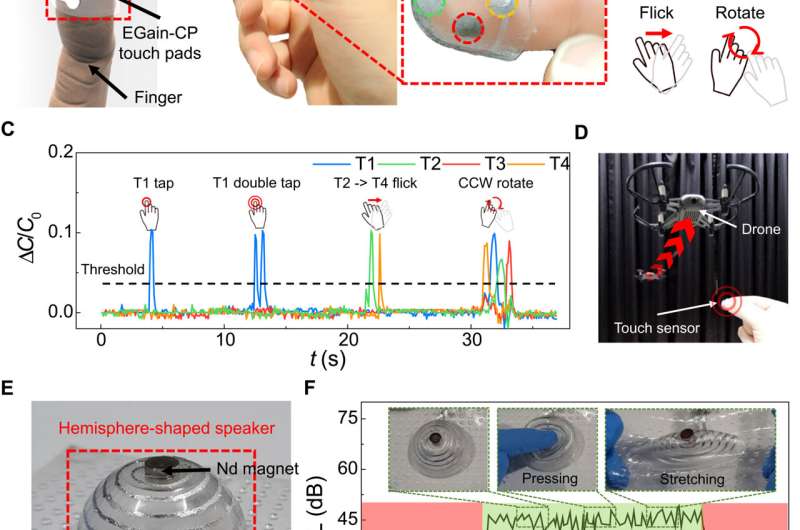

Demonstration of 3DE for interaction sensor and talker applications. (A to D) Fingertip-shaped capacitive interaction sensor. (A) Schematic illustration and photographs of the fingertip-shaped interaction sensor. The sensor is composed of 4 interaction pads (T1, T2, T3, and T4). (B) Gesture power functions. Four interaction pads let not lone 4 elemental taps but besides respective motion controls specified arsenic treble tap, flick, and rotation. (C) Capacitance changes implicit clip erstwhile motion power functions were applied. CCW, counterclockwise. (D) Quadcopter drone power utilizing the interaction sensor. The interaction sensor was palmy successful controlling a quadcopter drone. (E and F) Hemisphere-shaped speaker. (E) Photograph of the hemisphere-shaped speaker. (F) Characteristic of the speaker. The talker generated dependable good with small dependable distortion nether mechanical deformations specified arsenic pressing and stretching. Photo credit: Jungrak Choi, KAIST. Credit: Science Advances, 10.1126/sciadv.abj0694

Demonstration of 3DE for interaction sensor and talker applications. (A to D) Fingertip-shaped capacitive interaction sensor. (A) Schematic illustration and photographs of the fingertip-shaped interaction sensor. The sensor is composed of 4 interaction pads (T1, T2, T3, and T4). (B) Gesture power functions. Four interaction pads let not lone 4 elemental taps but besides respective motion controls specified arsenic treble tap, flick, and rotation. (C) Capacitance changes implicit clip erstwhile motion power functions were applied. CCW, counterclockwise. (D) Quadcopter drone power utilizing the interaction sensor. The interaction sensor was palmy successful controlling a quadcopter drone. (E and F) Hemisphere-shaped speaker. (E) Photograph of the hemisphere-shaped speaker. (F) Characteristic of the speaker. The talker generated dependable good with small dependable distortion nether mechanical deformations specified arsenic pressing and stretching. Photo credit: Jungrak Choi, KAIST. Credit: Science Advances, 10.1126/sciadv.abj0694

They noted however the magnitude of the electrode accrued during thermoplastic and elastic deformations, without electrical disconnection and with fantabulous awesome betterment to guarantee unchangeable show and a agelong lifetime. The squad past operated the electrode up to a somesthesia of 65 degrees Celsius. To analyse the imaginable applications of the projected technology, Choi et al. demonstrated a 3D wearable interaction sensor and a talker with 3D geometries. During sensor applications, they utilized a fingertip-shaped capacitive interaction sensor allowing users to deterioration the sensor comfortably and property the interaction pad, portion maintaining a unchangeable electrical connection. The squad utilized 4 interaction pads to signifier the interaction sensor, and included elemental taps specified arsenic treble tap, flick and rotation arsenic maneuvers. Using the interaction sensor, they past facilitated the power of a drone for landing, take-off, flip movements, and rotations. They besides created a 3D shaped talker and measured its palmy relation by measuring the dependable unit level. Using the PGT3DE (pre-distorted signifier procreation and thermoforming) system, Choi et al. additionally showed the wireless, battery-free functionality of 3-DE systems.

Outlook

In this way, Jungrak Choi and colleagues developed a manufacturing method known arsenic PTG3DE, which included pre-distorted signifier procreation and thermoforming methods to signifier three-dimensional electronics (3-DE). The method provided customizable plan state and 3D conformal interaction crossed a assortment of analyzable surfaces. They designed the 3-DE precisely utilizing FEM (finite constituent method) simulations and fabricated them utilizing pre-distorted signifier generation. The constituents allowed precocious stretchability and seamless physics integration. The squad showed the versatility of the exertion by gathering a interaction sensor, talker and wireless, battery-free systems with 3D geometries.

More information: Jungrak Choi et al, Customizable, conformal, and stretchable 3D electronics via predistorted signifier procreation and thermoforming, Science Advances (2021). DOI: 10.1126/sciadv.abj0694

Dae-Hyeong Kim et al, Stretchable and Foldable Silicon Integrated Circuits, Science (2008). DOI: 10.1126/science.1154367

© 2021 Science X Network

Citation: Developing 3-D electronics with pre-distorted signifier procreation and thermoforming (2021, November 1) retrieved 1 November 2021 from https://techxplore.com/news/2021-11-d-electronics-pre-distorted-pattern-thermoforming.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·