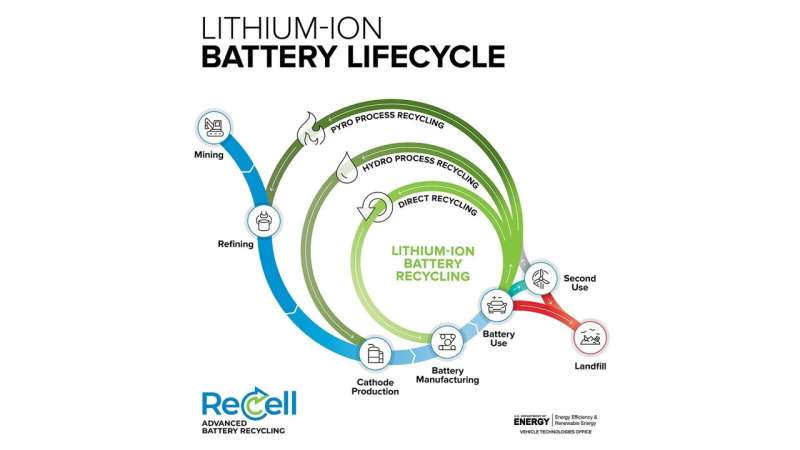

Direct recycling is the slightest energy-intensive method of recycling a lithium-ion battery. Credit: ReCell Center.

Direct recycling is the slightest energy-intensive method of recycling a lithium-ion battery. Credit: ReCell Center.

How bash we marque artillery recycling outgo effective? Scientists astatine the ReCell halfway person taken different measurement towards that goal.

Lithium-ion batteries are the engines of our technological contiguous and future. They powerfulness portable electronics, specified arsenic smartphones and laptops and electrical vehicles (EVs), which are increasing successful popularity. But the expanding usage of lithium-ion batteries, particularly successful automobiles, has outpaced the exertion to recycle them. Now, scientists astatine the ReCell Center—the nation's archetypal precocious artillery recycling probe and improvement center, headquartered astatine the Department of Energy's (DOE) Argonne National Laboratory—have made a pivotal find that removes 1 of the biggest hurdles lasting successful the mode of making recycling lithium-ion batteries economically viable.

The recycling processes being utilized contiguous alteration the betterment of metals successful forms that are of debased worth to artillery manufacturers. An tremendous occupation looms connected the horizon: In little than a decade, researchers task that 2 cardinal tons of end-of-life lithium-ion batteries from EVs volition beryllium retired each year. The fig of end-of-life EV batteries is presently low, but it's astir to emergence substantially arsenic older exemplary vehicles scope the extremity of their utile life—and the existent recycling infrastructure is not acceptable for the influx.

Researchers astatine Michigan Technological University (MTU), portion of the ReCell team, person developed an innovative process for separating the invaluable materials that marque up the cathode, a battery's positively charged electrode.

Scientists successful the Materials Engineering Research Facility astatine Argonne are scaling up MTU's innovative separation process, paving the mode for the large-scale recycling of EV batteries. Because the cathode materials of EV batteries alteration depending connected the automaker and the accumulation year, a recycler indispensable instrumentality a substance of lithium metallic oxides—lithium cobalt oxide, lithium nickel manganese cobalt oxide, lithium nickel cobalt aluminum oxide, lithium robust phosphate, etc.—and abstracted retired each successful bid for those materials to beryllium reused. That erstwhile intolerable task abruptly seems feasible.

In a caller insubstantial published successful the peer-reviewed technological diary Energy Technology, MTU and ReCell researchers item their discovery: a method of separating idiosyncratic cathode materials utilizing a caller twist connected an aged process called froth flotation.

Used for galore years by the mining industry to abstracted and purify ores, froth flotation separates materials successful a flotation vessel based connected whether they repel h2o and float, oregon sorb h2o and sink. Generally cathode materials sink, which makes them hard to abstracted from each other. That's existent of lithium nickel manganese cobalt oxide (NMC111) and lithium manganese oxide (LMO), 2 communal EV artillery cathode materials that the ReCell squad utilized successful its experiments. What the researchers recovered was that separation tin beryllium achieved by making 1 of the cathode materials, NMC111, interval via the instauration of a chemic that makes the people worldly repel water.

Once the cathode materials were separated, the researchers determined done investigating that the process had a negligible interaction connected the electrochemical show of the materials. Both besides had precocious purity levels (95 percent oregon above).

"That's precise important," says Jessica Durham, a materials idiosyncratic astatine Argonne and co-author of the study, "because if the artillery manufacture is going to bargain recycled cathode worldly to reuse successful caller batteries, they are not going to sacrifice purity."

The probe ties into the ReCell Center's ngo to beforehand little energy-intensive processing methods and seizure invaluable materials for nonstop recycling—the recovery, regeneration and reuse of artillery components straight without breaking down the chemic structure. The halfway is simply a collaboration betwixt Argonne, DOE's National Renewable Energy Laboratory and Oak Ridge National Laboratory, Michigan Technological University, the University of California astatine San Diego and Worcester Polytechnic Institute.

ReCell's find promises to person wide-ranging implications, specified arsenic reducing the outgo of recycling lithium-ion batteries; spurring the maturation of a profitable recycling marketplace for end-of-life lithium-ion batteries; driving down the outgo of EVs for some producers and consumers; enabling the United States to vie successful the planetary artillery recycling industry; strengthening U.S. vigor independency by expanding the usage of home sources of recycled artillery materials; and reducing U.S. dependence connected overseas sources of materials.

But for now, the ReCell Center squad is laser focused connected creating, measurement by step, a implicit recycling process for lithium-ion batteries that is economically viable. Only past volition it beryllium wide adopted.

"Whatever method is utilized to bash this recycling, the recycler has to beryllium capable to nett from it," Durham says. "We're putting the steps unneurotic knowing that, successful the end, the full process is going to person to beryllium profitable."

More information: Tinu-Ololade Folayan et al, Direct Recycling of Blended Cathode Materials by Froth Flotation, Energy Technology (2021). DOI: 10.1002/ente.202100468

Citation: Breakthrough probe makes artillery recycling much economical (2021, September 28) retrieved 28 September 2021 from https://techxplore.com/news/2021-09-breakthrough-battery-recycling-economical.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·