September 8, 2021 feature

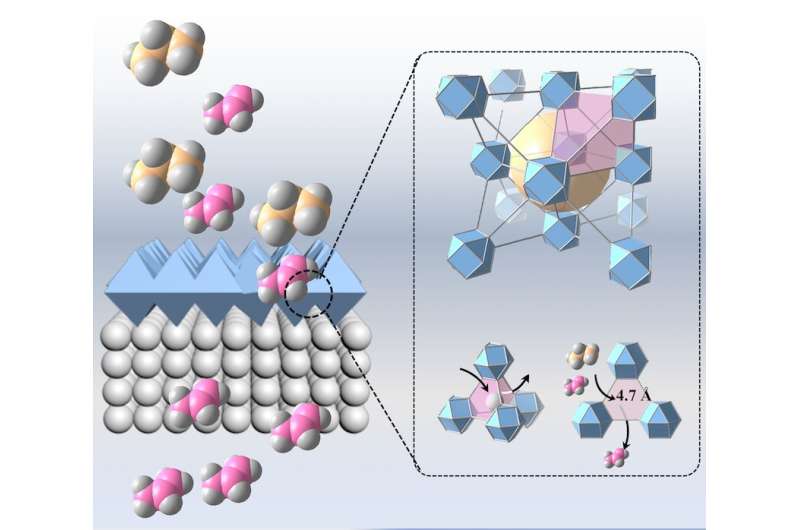

Schematic membrane-based separation process (left) and operation objection of the Zr-fum-fcu-MOF membrane (right). Credit: Zhou et al.

Schematic membrane-based separation process (left) and operation objection of the Zr-fum-fcu-MOF membrane (right). Credit: Zhou et al.

The separation of airy hydrocarbon mixtures is among the astir important petrochemical and concern processes. This process is presently regarded arsenic highly vigor intensive, arsenic it has truthful acold been carried retired utilizing accepted techniques, specified arsenic cryogenic distillation.

An alternate mode of separating airy hydrocarbons could beryllium to usage membrane-based separation processes. In opposition with cryogenic distillation and different accepted processes, membrane-based separation is not driven by heat, frankincense it could assistance to trim the wide vigor requirements of airy hydrocarbon separation. Over the past fewer years, scientists worldwide person frankincense been trying to make and place caller materials that could beryllium utilized to fabricate membranes to transportation retired specified energy-intensive separations.

Researchers astatine King Abdullah University of Science and Technology (KAUST) person precocious introduced a versatile electrochemical directed-assembly strategy to fabricate membranes for the separation of hydrocarbons. This strategy, introduced successful a insubstantial published successful Nature Energy, allowed them to fabricate metal-organic framework arsenic continuous bladed films and deploy them arsenic membranes that could trim the vigor input successful hydrocarbon separation processes by astir 90% compared to accepted azygous distillation processes.

"Our erstwhile explorations connected the design, find and improvement of metal-organic frameworks (MOFs) person unveiled a caller level based connected the face-cantered cubic (fcu) MOFs, which turned retired to beryllium amendable to ultra- good tuning of their pore-apertures, positioning the fcu-MOFs arsenic suitable sorbents for assorted cardinal separations," Mohamed Eddaoudi, 1 of the researchers who carried retired the study, told TechXplore. "The main nonsubjective of our survey was to instrumentality them to the adjacent level and process these selected adsorbent materials into applicable membranes that connection precocious permselectivity astatine industrially applicable precocious pressures and nether assertive conditions. In summation to that they tin beryllium casual to manufacture successful a scalable and robust fashion."

Fabricating defect-free polycrystalline MOF membranes is precise challenging, arsenic it requires a highly controllable maturation process. To fabricate their membranes, Eddaoudi and his colleagues utilized an electrochemical attack that works by applying a controlled outer existent to beforehand the crystallization and intergrowth of polycrystalline fcu-MOF bladed movie connected a porous support.

"Compared with the accepted solvothermal growth, this electrochemical attack is highly controllable, truthful high-quality bladed films tin beryllium obtained," Sheng Zhou (Ph.D. pupil and archetypal author) explained. "Also, the fabrication conditions are overmuch milder and faster than utilizing different methods, requiring lone country temperature, atmospheric unit and abbreviated maturation clip (two hours). As a result, this strategy is much applicable and scale-up friendly."

By successfully combining reticular chemistry with an electrochemical synthetic approach, Eddaoudi and his colleagues were capable to fabricate continuous, defect-free fcu-MOF membranes with stable, intrinsic molecular sieving properties. These properties marque the membranes they created peculiarly promising for the separation of airy hydrocarbons.

In addition, the researchers were the archetypal to make a methodology that tin beryllium utilized to find the close conditions for fabricating closed thin-film membranes based connected a bid of MOFs with assorted types of linkers. In the future, membranes created utilizing the strategy they developed could importantly heighten hydrocarbon separation processes.

"The deployment of our Zr-fum-fcu-MOF membranes successful a hybrid membrane–distillation strategy offers the imaginable to alteration the vigor input by astir 90% compared to a accepted azygous distillation process for propylene/propane separation," Dr. Osama Shekhah ( elder probe scientist) said. "We are presently trying to grow our membrane plan and fabrication to different systems, to code much challenging yet important separations. At the aforesaid time, we are moving connected assorted way to scale-up the fabrication of our membranes, including preparing large-scale hollow fibre membranes." Eddaoudi said.

More information: Sheng Zhou et al, Electrochemical synthesis of continuous metal–organic model membranes for separation of hydrocarbons, Nature Energy (2021). DOI: 10.1038/s41560-021-00881-y

© 2021 Science X Network

Citation: A strategy to fabricate metal-organic model membranes for the separation of hydrocarbons (2021, September 8) retrieved 8 September 2021 from https://techxplore.com/news/2021-09-strategy-fabricate-metal-organic-framework-membranes.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·