The volatile quality of abstraction rocket engines means that galore aboriginal prototypes extremity up embedded successful ungraded banks oregon decorating the tops of immoderate trees that are unfortunate capable to neighbour investigating sites. Unintended explosions are successful information truthful communal that rocket scientists person travel up with a euphemism for erstwhile it happens: rapid unscheduled disassembly, oregon RUD for short.

Every clip a rocket engine blows up, the root of the nonaccomplishment needs to beryllium recovered truthful that it tin beryllium fixed. A caller and improved motor is past designed, manufactured, shipped to the trial tract and fired, and the rhythm begins again—until the lone disassembly taking spot is of the slow, scheduled kind. Perfecting rocket engines successful this mode is 1 of the main sources of developmental delays successful what is simply a rapidly expanding space industry.

Today, 3D printing technology, utilizing heat-resistant metallic alloys, is revolutionizing trial-and-error rocket development. Whole structures that would person antecedently required hundreds of chiseled components tin present beryllium printed successful a substance of days. This means you tin expect to spot galore much rockets blowing into tiny pieces successful the coming years, but the parts they're really made of are acceptable to go larger and less arsenic the backstage assemblage abstraction contention intensifies.

Rocket engines make the vigor equivalent of detonating a ton of TNT each second, directing that vigor into an exhaust that reaches temperatures good implicit 3,000℃. Those engines that negociate this without rapidly dissembling successful an unscheduled manner instrumentality astatine slightest 3 years to technologist from scratch, astir of which is taken up by the cyclical process of redesign, rebuild, refire and repeat.

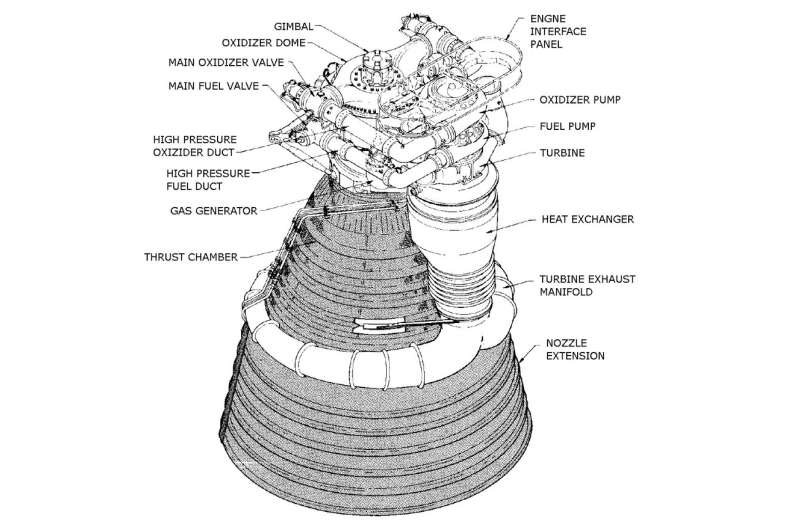

That's due to the fact that rocket engines are incredibly complex. The Saturn V's F-1 engines that blasted Neil Armstrong towards the Moon successful 1969 each had 5,600 manufactured parts. Many of them were sourced from antithetic suppliers and had to beryllium individually welded oregon bolted unneurotic by hand, which took time.

This lengthy, costly process mightiness person been good successful the 1960s, with the US authorities funneling wealth into Nasa to substance the abstraction race, but for private companies it simply takes excessively long.

Add rocket fuel

The cardinal to accelerated motor improvement is to trim the fig of parts, which reduces the clip it takes to assemble the motor and the disruption caused by proviso concatenation delays. The easiest mode to bash this is to alteration manufacturing processes. Space companies are present moving distant from subtractive manufacturing processes—which region worldly to signifier a part—to additive manufacturing processes that physique up a portion by adding worldly to it spot by bit.

The F-1 rocket engines that launched Apollo 11 towards the Moon were made of thousands of idiosyncratic parts. Credit: Nasa/Wikimedia

The F-1 rocket engines that launched Apollo 11 towards the Moon were made of thousands of idiosyncratic parts. Credit: Nasa/Wikimedia

That means 3D printing. Increasingly, engineers are favoring a process called selective laser sintering to 3D-print rocket motor parts successful an additive process. It works by archetypal laying down a furniture of metallic powder, earlier melting shapes into the pulverization with lasers. The metallic binds wherever it's melted, and remains pulverization wherever it's not. Once the signifier has cooled, different furniture of pulverization is added, and the portion is built up layer by layer. For rocket engines, an Inconel copper ace alloy pulverization is used, due to the fact that it tin withstand precise precocious temperatures.

Selective laser sintering allows for aggregate components to beryllium printed in-house, arsenic 1 unified part, successful a substance of days. When an RUD occurs and the responsibility is found, engineers tin make a hole utilizing 3D modeling software, integrating highly analyzable parts into caller rocket engines for trial firing a fewer days later.

Using 3D printing besides helps manufacturers trim the value of the implicit rocket, arsenic less nuts, bolts and welds are required to nutrient their analyzable structure. 3D printing is particularly utile successful manufacturing an engine's analyzable regeneratively cooled nozzle, which routes chill substance astir the blistery motor to simultaneously chill the motor walls and preheat the acold substance earlier combustion.

This single-piece rocket thrust enclosure connected show successful Hall 2C Booth C354 astatine the #ParisAirShow creates a reduced assembly constituent with integrated interior ducts and latticed cooling channels. https://t.co/x7JddUk4yl pic.twitter.com/Q1WnErNs07

— SLM Solutions (@SLMSolutions_NA) June 19, 2019A redesign of the Apollo F-1 engines utilizing 3D printing reduced the fig of parts from 5,600 to conscionable 40. No institution has yet to trim this fig down to one, but it's undeniable that 3D printing has brought astir a caller property of fast, responsive rocket motor development.

Business viable

That matters for backstage abstraction enterprises. Building a rocket isn't cheap. Investors whitethorn get flighty arsenic the RUD scrap heap begins to mount. Companies vying to motorboat payloads into abstraction instrumentality a nationalist relations sound whenever they're forced to propulsion backmost their motorboat schedules connected relationship of faulty rockets.

Virtually each caller rocket companies and abstraction startups are adopting 3D metal-printing technology. It accelerates their improvement phase, helping them past the important years earlier they negociate to get thing into space. Of enactment are Rocket Lab, which uses its 3D-printed motor to motorboat rockets from New Zealand, and Relativity Space which is 3D printing its full rocket. In the UK there's, Skyrora and Orbex. The second aims to motorboat a rocket utilizing a 3D-printed motor arsenic aboriginal arsenic 2022.

It remains to beryllium seen whether an full rocket, including its engine, tin beryllium 3D-printed successful erstwhile piece. But that's intelligibly the absorption of question for an manufacture successful which light-weight, complex, in-house manufacturing volition specify which payloads participate orbit—and which extremity up rapidly dissembling astatine an inopportune moment.

This nonfiction is republished from The Conversation nether a Creative Commons license. Read the original article.![]()

Citation: 3D-printed rocket engines: The exertion driving the backstage assemblage abstraction contention (2021, September 20) retrieved 20 September 2021 from https://techxplore.com/news/2021-09-3d-printed-rocket-technology-private-sector.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

English (US) ·

English (US) ·